MRO Spares

-

Read More »

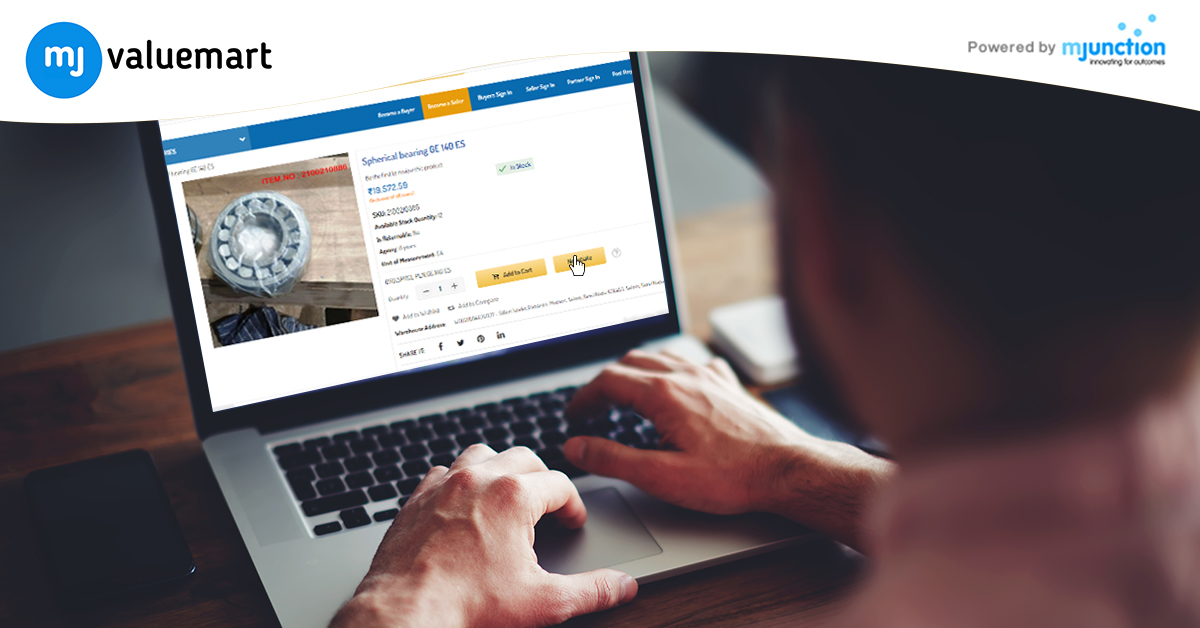

It’s not an easy task to procure unused MRO spares, the purchase method involves cost-cutting and quality assurance products. But procurement of MRO surplus often gets overlooked. Selling and buying spare parts in the t...

-

Read More »

MRO spare parts play an important role in maintaining the uninterrupted functioning of machinery and equipment. Proper classification of these spares is crucial for efficient inventory management, streamlined procurement processes, and enhanced ...

-

Read More »

In the ever-changing landscape of MRO spares management, staying abreast of the latest trends is important. By remaining up-to-date with the latest trends in MRO spares management, businesses can improve efficiency, minimise costs, enhance inven...

-

Read More »

Maintenance, repair and operating (MRO) spare parts play an important role in ensuring that production equipment and facilities continue to function smoothly. However, they can malfunction due to various reasons including poor quality, improper ...

-

Read More »

When it comes to inventory management, MRO stands for Maintenance, Repair and Operations. This inventory includes items such as spare parts, cleaning supplies, lubricants, safety equipment and tools to keep a business running smoothly. To effect...

-

Read More »

Stock obsolescence occurs when a company has an excess inventory of old or outdated products, particularly maintenance, repair, and operations (MRO) spare parts, that are no longer needed or wanted. Stock obsolescence can lead to increased stora...

-

Read More »

In many businesses, finding the right MRO supplies, negotiating prices, and managing deals are an important part of ensuring that business keeps operating smoothly. Buying MRO spares present businesses massive opportunities for growth, inn...

-

Read More »

The foundation of every successful business is a good idea and hard work. However, to continue to run a booming business needs continuous efforts. One such area that needs attention is inventory management. Proper inventory management is essenti...

-

Read More »

MRO stands for Maintenance, Repair, and Operations. The purpose of MRO inventory is to make sure the company will have spare parts, materials, and supplies available as and when needed. For this, the company needs inventory management. By...

-

Read More »

Inventory makes up for the maximum spending of a company. Buying inventory is not just raising a purchase order. Rather it is about paying close attention to how much inventory companies should order and when to do it to reduce carrying an...