Mechanical

-

Read More »

Material handling equipment plays an important role in companies that deal with the handling and storage of bulk materials. In general, material handling equipment refers to machinery and tools specifically designed to facilitate the movement, c...

-

Read More »

A welding machine, also known as a welder, plays an important role in metalworking. This powerful tool utilises thermal energy to fuse or separate metal components by melting them. With its ability to generate intense heat, a welding machine ser...

-

Read More »

Emergency response and spare parts safety are important areas to address. By having a well-defined emergency plan and ensuring safety in managing machine spare parts, organisations can effectively respond to crises and minimise risks. Here we di...

-

Read More »

A material handling equipment is any mechanical equipment, which is used for storing and controlling products and goods. It is used in every stage of a product's lifecycle, from manufacturing to disposal. For example, forklifts can lift and move...

-

Read More »

Welding machines are very important tools used in different industries. They are used for joining two or more pieces of metal together by using heat and pressure. These machines consist of several important parts that work together to facilitate...

-

Read More »

Whether it is heavy machinery used in the construction industry or manufacturing equipment used in factories, machinery spares play an important role in keeping these machines running efficiently. These spare parts are necessary for several reas...

-

Read More »

In recent years, there has been a trend of MSMEs, traders and small businesses buying unused mechanical spares online. Buying mechanical instruments online offers them a wide range of options, making it easy to find the right spare parts for the...

-

Read More »

Hydraulic systems are used in many industries as they are capable of moving heavier loads than mechanical, electrical or pneumatic systems. As they use fewer parts, they are easy to maintain. You can buy unused and genuine hydraulics and pneumat...

-

Read More »

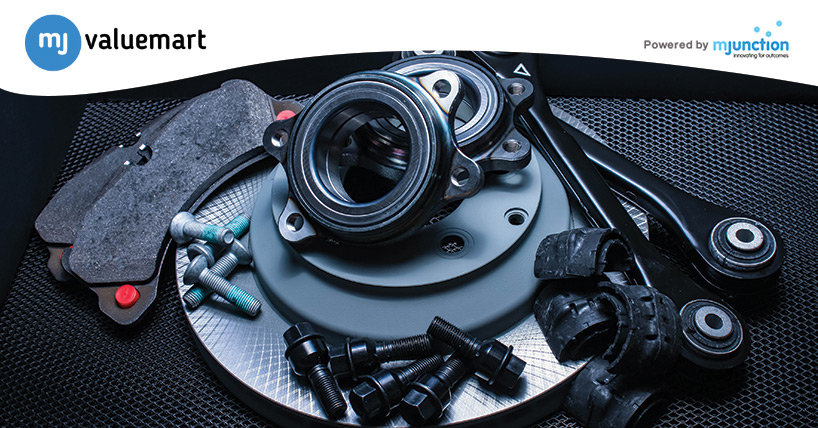

Gear boxes are used in several industries. They increase torque while reducing the speed. Gear boxes are used in the machineries which are meant for manufacturing end products such as paper, steel products, cement and fertilisers. Often, gear bo...

-

Read More »

Proper inventory management can help eliminate delays associated with unplanned breakdowns and reduce process time and cost. Shafts are among the most important industrial spares. As one of the leading e-marketplaces for genuine and unused indus...