Blog

-

Read More »

Read More »Finding the ideal balance between quality and cost-effectiveness is one of the most sig...

Read More »

MRO spare parts play an important role in maintaining the uninterrupted functioning of machinery and equipment. Proper classification of these spares is crucial for efficient inventory managemen...

Read More »

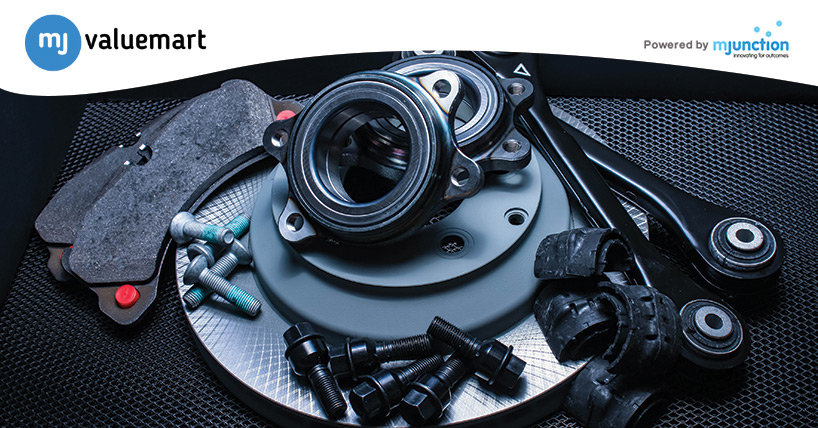

Industrial spares play an important role in ensuring uninterrupted operations and optimal performance of machinery and equipment across diverse industries. Efficient procurement of these spares is of utmost impo...

Read More »

In the ever-changing landscape of MRO spares management, staying abreast of the latest trends is important. By remaining up-to-date with the latest trends in MRO spares management, businesses ca...

Read More »

Material handling equipment plays an important role in companies that deal with the handling and storage of bulk materials. In general, material handling equipment refers to machinery and tools specifically desi...

Read More »

A welding machine, also known as a welder, plays an important role in metalworking. This powerful tool utilises thermal energy to fuse or separate metal components by melting them. With its ability to generate i...

Read More »

Emergency response and spare parts safety are important areas to address. By having a well-defined emergency plan and ensuring safety in managing machine spare parts, organisations can effectively respond to cri...

Read More »

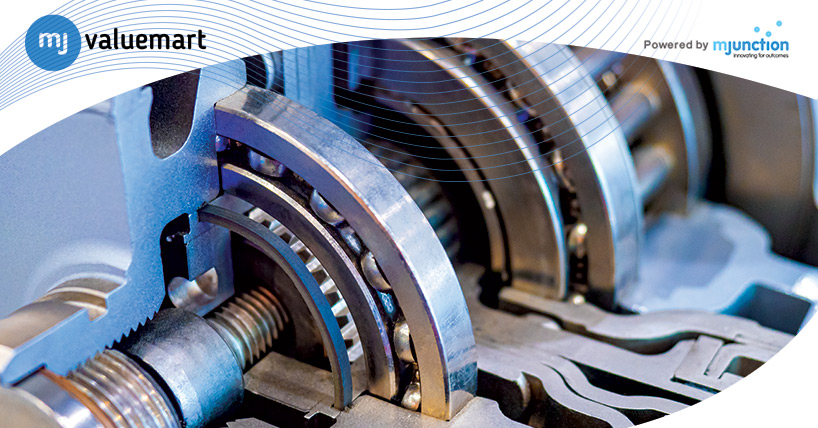

Procuring transmission parts is pivotal for industries in India that are heavily dependent on machinery and equipment. Efficient sourcing of these parts is crucial for ensuring uninterrupted operations, minimisi...