What are the Different Uses of Gear Box? What Details are Required to Buy a Gear box?

A gear box transmits mechanical energy to an output device and is an essential component of machines used in various industries. As a leading e-marketplace for unused and genuine MRO spares, we explain some of the different types of gear boxes and what are their uses:

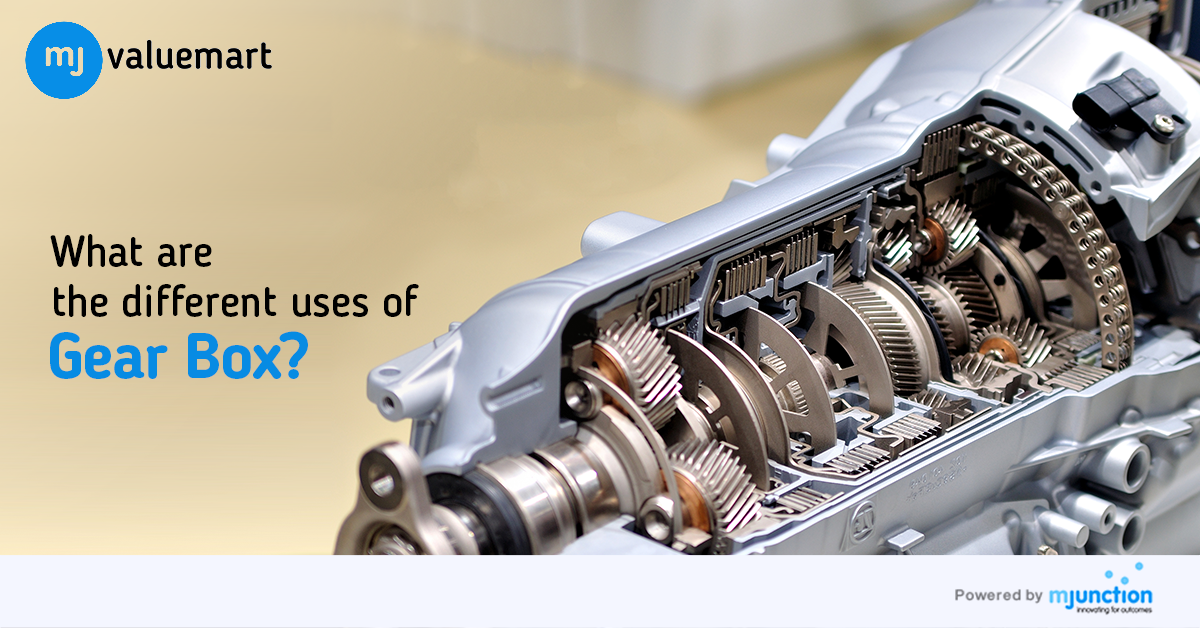

Helical gear box: Helical gears are at an angle to the shaft. This leads to contact of more than one teeth during operation of the gear box, which helps the gear carry more load. Hence, helical gear box can withstand extremely high output torque, silent in operation and has a long service life. A helical gear box is typically used where high mechanical power is needed. Helical gear boxes are used in industrial units where plastics, cement and rubber are manufactured. These gear boxes are used in crushers, extruders, coolers and conveyors, which are all low-power applications. Helical gear boxes are also used in fertilizer industries, printing industries, earth-moving industries, steel rolling mills and textile industries.

Bevel helical gear box: This Bevel helical gear box has curved teeth located on the surface close to the rim of the unit. The ground circular arc teeth provide rotary motions between non-parallel shafts. These are widely used in quarries, in the mining industry and in conveyors.

Worm gear box: It is a reduction gear box that is generally used to take a rated motor speed and produce a low-speed output. They can solve space-saving problems because the worm gear boxes are sleek and compact.

Lay change gear box: In a lay shaft gear box, a lay shaft is used for transferring the output of the engine to the main shaft. This is done by the meshing of a gear on the lay shaft to the gear on the clutch shaft.

Planning to buy a gear box: Here are some details you will need to know

Intended application: There are a variety of gear boxes available in the market that are capable of fulfilling diverse requirements. The first thing you should do is size the load and know the exact application. Buy gear boxes that fit the intended application.

Service factor: Before buying a gear box, the service factor needs to be figured out. To define a service factor, you need to know the type of input, operating hours, elevated ambient temperature and any shock or vibration present during the application.

- Shock load: High impact loads means increased wear. This wear could cause premature failure of a gear box if not taken into at the time of sizing.

- Housing: If a gearbox will be used in an environment where chances of corrosion are high, a stainless steel or aluminium gear box is ideal for such applications.

Looking for gear boxes for your business? Buy unused, genuine MRO spares at discounted prices

mjvaluemart is an e-marketplace where you will find genuine MRO spares such as gear boxes, couplers, worm wheel shaft, worm shaft and fastners. at discounted market prices. Buyers can register and log in to check unused products available across the country at competitive prices, place the products online and get them delivered at their doorstep. In some cases, inspection reports of the products can also be made available to the buyers by the sellers. To become a registered partner, submit your request.